SERVICIOS RULISA HYDRAULIC BLOCKS

Zinc - Níquel

Ponemos a disposición de los clientes un recubrimiento de Cinc-Níquel para todas nuestras piezas de acero y fundición, asegurando una resistencia a la corrosión de 3.356 horas en cámara de niebla salina, muy superior incluso a C5H (1.500 horas en cámara de niebla salina)

Pavonado

Este baño le ofrece las propiedades y características que a continuación detallamos:

- Se produce por inmersión unas capas negras uniformes de óxido ferroso, vistosas y brillantes sobre superficies pulidas y mates sobre hierro o acero decapado o arenado.

- La capa de pavonado tiene una moderada resistencia a la corrosión y cumplen con las especificaciones MIL-C-13924 A, Clase 1. Se consigue mayor resistencia cuanto más bajo es el contenido en carbón.

- Estas capas tienen una resistencia entre dos y seis horas en niebla salina al 20%, lo cual es suficiente para piezas que están en interiores. Con una capa de aceite, cera o laca se obtiene una protección adicional para dichas piezas.

- La capa de Pavonado que se consigue en las piezas va de 1 a 2 micras.

- Se recomienda para muchos aceros con bajo contenido en cromo.

- La realización del proceso de pavonado se efectúa a temperaturas de 150 grados, por lo tanto no suele haber problemas de deformación en las piezas.

En general, la aplicación de este recubrimiento mejora y alarga la vida de las piezas y reduce costos de materiales caros dado que se pueden utilizar otros menos costosos y más sencillos de mecanizar.

Níquel químico

El níquel químico es un recubrimiento técnico compuesto de níquel y fósforo (9-12%). Se aplica con un proceso químico en el que no interviene la utilización de energía eléctrica. Es un proceso no electrolítico.

El proceso de níquel químico es una reducción auto catalítica en la que los iones de níquel, en presencia de fósforo, se transforman en una combinación metálica de níquel y el mismo fósforo que se deposita en la pieza.

El revestimiento es aplicado sin corriente. El espesor de la capa es uniforme y regular en toda la pieza. Por esta razón, se pueden recubrir piezas con geometrías muy complejas sin necesidad de mecanizaciones posteriores. Al ser un proceso que se realiza a bajas temperaturas las piezas no sufren ningún tipo de deformaciones incluso si la capa de níquel-fósforo se trata térmicamente.

Las ventajas que obtienen nuestros clientes al tratar sus piezas con níquel químico son.

- Buena protección contra la corrosión

- Alta dureza: de 450 HV /45 HRC) a 900 HV (62 HRC) con tratamiento térmico de la capa depositada.

- Buena resistencia al desgaste.

- Bajo coeficiente de fricción

- Buenas propiedades físicas para aplicarlas en muchos ramos de la industria.

Fosfatado

Los recubrimientos fosfatados son usados en piezas de metal, fundamentalmente de acero, para evitar la corrosión, mejorar la lubricación o como base para recubrimientos posteriores.

El pavonado está fundamentado en una solución de ácido fosfórico (H3PO4) y sales de fosfato que se aplican por aspersión o inmersión y que reaccionan con la superficie del metal formando una capa cristalina de fosfato no soluble.

Estos recubrimientos pueden ser aplicados también en otros metales, como aluminio, cinc, cadmio y estaño. Los tipos de fosfatos que se mplean principalmente son de manganeso, hierro y zinc. El fosfato de manganeso se usa para eveitar la corrosión y mejorar la lubricación del metal. Sólo se aplica por inmersión. El fosfato de hierro es utilizado generalmente como base para recubrimientos posteriores y su aplicación es por inmersión o aspersión.

El fosfato de zinc se utiliza para prevenir la oxidación y como capa base lubricante o capa base para recubrimientos posteriores. Se aplica por aspersión e inmersión.

Anodizado

El anodizado es una técnica utilizada para modificar la superficie del Aluminio mediante la oxidación alumínica que protege la pieza, conocida como alumina.

Esta capa se consigue por medio de electrolisis consiguiendo una capa en micras que consigue una mayor resistencia y durabilidad del aluminio.

La protección del aluminio dependerá de la capa o micraje que se cree en la pieza.

Características:

- Decorativo: permitiendo aplicar colores en las piezas, rojos, verdes, azules, negros, etc.…

- Resistencia: Dureza, gran resistencia a la corrosión incluso en ambientes marinos e industriales, con gran resistencia a la abrasión, etc…

- Aislamiento: Eléctrico y térmico.

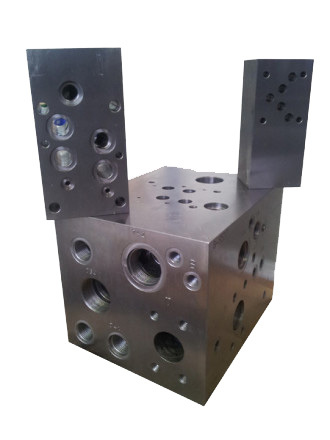

Rulisa Hydraulic Blocks es el número 1 en fabricación de bloques hidráulicos con un único objetivo: la más alta calidad.